May 11th, 2022

Use of Simulation from Design through Operations Support

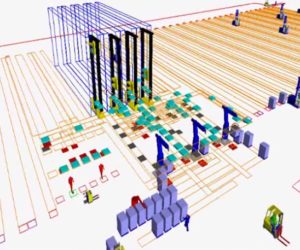

System simulation consists of computer programs used to model the operation of a system. Generally, the simulation models the physical and logic operation of the system. Elements modeled can include automated equipment(AS/RS cranes, shuttles, Rovers, conveyors, robotics), manual operations(walking, picking, packing), manually controlled equipment(fork trucks, pallet jacks), and related process elements. Data files are then used to provide demand or initial conditions(receipts, orders, and inventory levels), operating parameters(speeds, accelerations/decelerations, positioning times, walking times, processing times), and certain operating rules(receiving windows, shipping windows and cutoffs, wave plans and durations). Depending on the requirements, demand in a simulation can be created statistically using a variation of a peak rate or by using actual receipts and actual orders. The statistical model is simpler and faster to generate but might lack the variability of the actual operation.